Gas valves are used to control the flow of gas in different environments and conditions. These valves feature a ball mechanism that opens and closes the gas flow inside the pipe when the valve handle is turned. The most important aspect of ensuring the safety and longevity of these valves is proper care and maintenance. Below, we discuss several key points in this regard.

Acquiring Accurate Information about Gas Valves

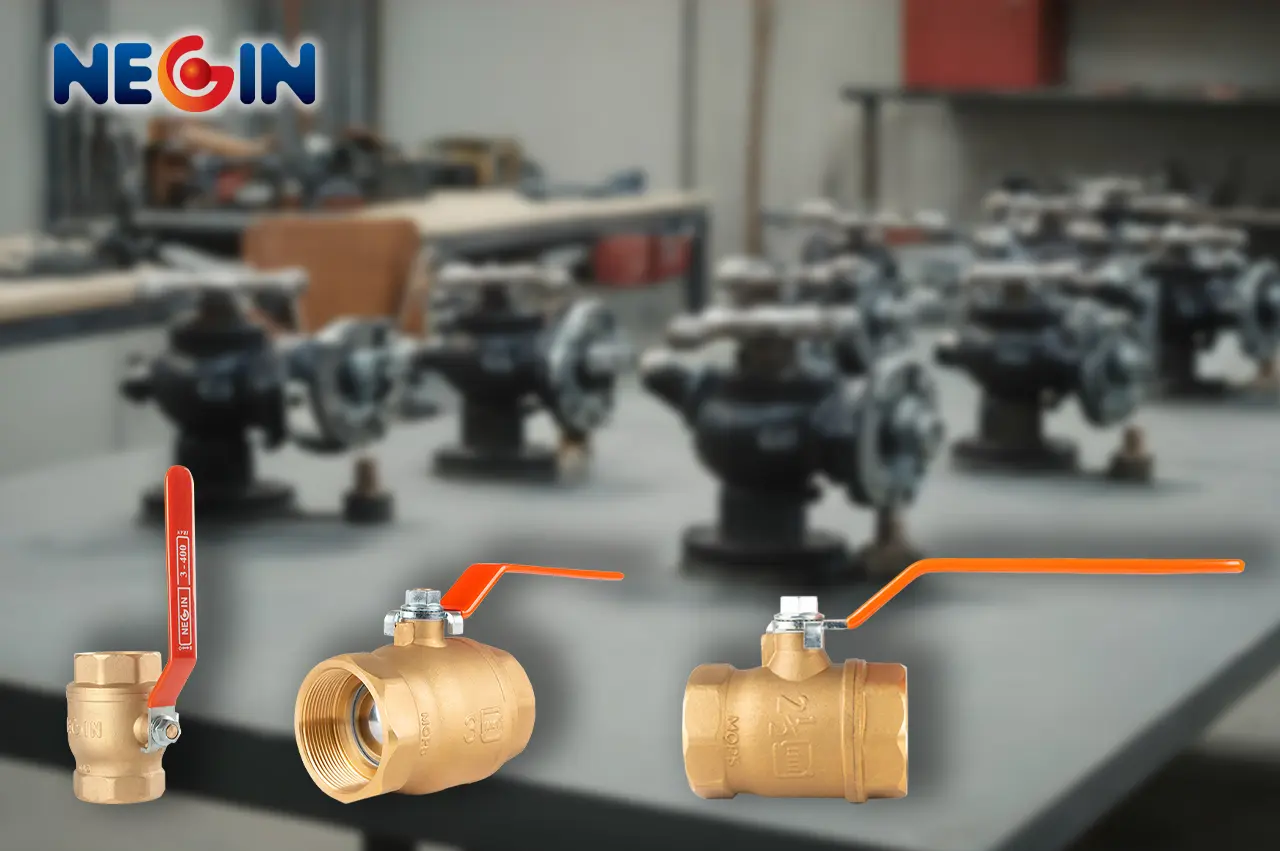

A crucial aspect of maintaining gas valves, which many may overlook, is having the necessary information about the product. Gas valves come in various types, each with its own specific functions. Knowing how each valve operates is essential for understanding the appropriate maintenance methods. For example, one of the gas valves from Negin Shir is the Negin 101 model, made from MS 58 brass. If using this gas valve, it is important to learn about its operation.

Purchasing Gas Valves with Appropriate Technical Specifications and Standards

Proper maintenance starts with purchasing gas valves that meet the correct technical specifications and standards. The materials used in these valves should be compatible with gas. Negin Shir’s gas valves are made from high-quality copper. All necessary standards, considering the temperature and nature of the fluid, are adhered to during manufacturing.

Proper Installation for Effective Maintenance

The next step after acquiring high-quality and standard gas valves is their correct installation. Proper maintenance begins with correct installation, which should be performed by professionals. Proper installation directly affects the optimal performance of these products. Many people might think installing gas valves is easy, but each type, whether simple or complex, has its specific installation and setup patterns. Following all installation details prevents short-term failures.

Cleaning the Exterior of Gas Valves

Regular and routine cleaning is one of the most effective ways to maintain gas valves. These valves should be cleaned periodically, on an annual and monthly basis, to directly impact their lifespan. Various contaminants in industrial, commercial, and residential environments can degrade these valves. Gas valves are particularly sensitive to environmental contaminants. The internal mechanisms of gas valves, whether rotary or linear, must be regularly cleaned to ensure proper operation.

Timely Inspection for Proper Maintenance

Timely inspection and addressing technical issues are also vital for the proper maintenance of gas valves. Gas valves are commonly used in both industrial and residential settings. Each valve has its own specific structure that needs to be checked at regular intervals. Inspections should include:

Checking various mechanical and technical components

Evaluating the performance of mechanical controls

Inspecting the valve body for rust

Checking for wear and cracks

Inspecting valve connections for leaks

Prompt Repair of Gas Valves

Even with proper maintenance, gas valves may still encounter issues. These mechanical components are made up of various technical and electrical parts, and failure of any part can affect the overall functionality of the valve. Timely repair of smaller components within the valve can prevent further damage and higher repair costs. Industrial valve repairs include several tasks that fall under maintenance work, contributing to their longevity. Important repair tasks include:

Lubricating various moving parts

Replacing defective parts

Repairing damaged components

Using Machining Techniques for Gas Valve Restoration

Another method for proper maintenance of gas valves is machining. Long-term use in various industrial and domestic settings can weaken valve connections, increasing the risk of gas leaks, which can be hazardous. One preventive measure is machining the flange surfaces of valves to eliminate the risk of leaks. Depending on the condition, this might be done without removing the valves, though significant damage may require disconnection. Machining is a simple process that significantly enhances the lifespan of gas valves.

Machining can be considered one of the best methods for maintaining gas valves. This technique helps repair surface and deep cracks that develop over time. Removing rust and other residues from the exterior and interior surfaces of valves is a crucial part of this process.

Before implementing all these maintenance methods, careful selection of the product is essential. Negin Shir Industrial Company, a reputable provider of various gas and industrial valves, offers products like the Negin 103 and 104 models, also made from brass alloys. The availability of different sizes for these models ensures that users can choose the best fit for their piping and connection needs.